The Baltic Towers facility in Gdańsk is a modern industrial investment dedicated to producing offshore wind turbine towers, supporting Poland's transition to renewable energy. My client Pekabex is responsible for delivering and assembling prefabricated reinforced concrete structures for this project, ensuring high durability and efficiency. The facility will play a key role in supplying components for offshore wind farms in the Baltic Sea.

I had the opportunity to capture the scale and precision of this innovative construction, highlighting the advanced solutions implemented by Pekabex and Erbud.

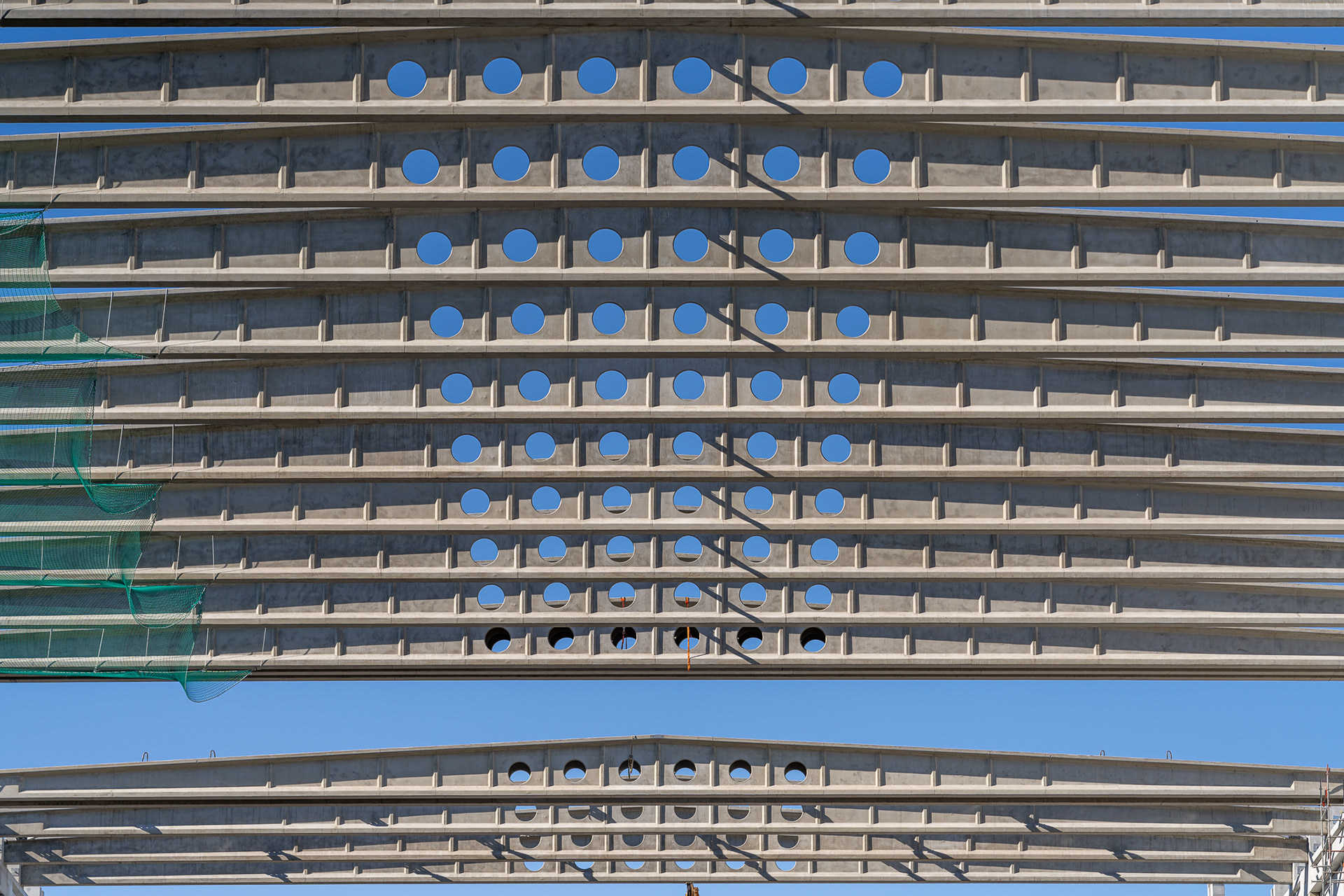

The construction of the Baltic Towers facility in Gdańsk involves the use of massive prefabricated reinforced concrete columns, each weighing approximately 75 to 80 tons. These columns have a cross-sectional dimension of 0.6 meters by 2.8 meters and reach heights up to 33.6 meters. The main production hall spans 136 meters in width and 377 meters in length, with a central nave height of 35.5 meters. The roof structure includes double-pitched girders with a maximum span of 55 meters, each weighing around 65 tons. Additionally, crane beams measuring 1.8 meters in height and weighing 35 tons are installed to support heavy-duty cranes within the facility.

The facility is designed to produce sections of wind turbine towers up to 50 meters in length, weighing up to 500 tons, and with diameters reaching 10 meters. This capacity enables the production of towers for offshore wind turbines with capacities of 15 MW and above.

The construction process involves advanced engineering techniques, including the use of two cranes—one with a 500-ton capacity and a secondary 300-ton crane—to safely lift and position the massive columns. The project also employs specialized transport equipment, such as Nachläufer trailers, to handle the oversized prefabricated elements.